3D printing, also known as additive manufacturing, has become a transformative technology in the fields of design and engineering, enabling professionals to innovate faster and more effectively. This innovation is primarily driven by several key factors that enhance the overall production and design process.

1. Rapid Prototyping

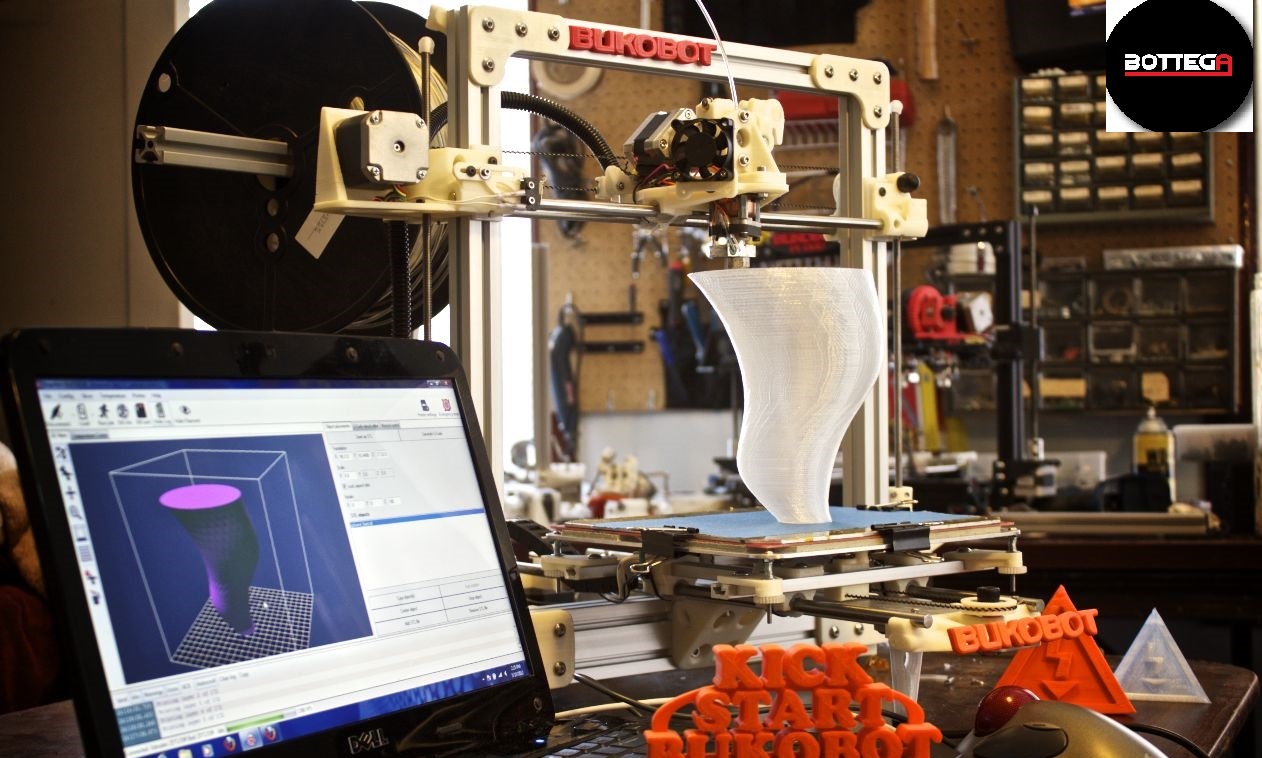

One of the most significant advantages of 3d printing service is its capacity for rapid prototyping. Traditionally, creating prototypes could take weeks or even months, involving lengthy processes of tooling and assembly. With 3D printing, designers can produce prototypes directly from digital models in a matter of hours or days. This swift production allows for multiple iterations, enabling engineers to test and refine their designs quickly without incurring substantial costs.

2. Cost Efficiency and Reduced Waste

3D printing eliminates the need for expensive molds and tooling, which can be a major cost in traditional manufacturing methods. By using materials more efficiently and generating less waste, 3D printing not only saves money but also promotes sustainable practices. This cost-effectiveness is particularly beneficial for small batch production and complex designs, allowing for greater experimentation and faster innovation.

3. Design Freedom and Customization

The flexibility of 3D printing allows designers to create intricate geometries and customized parts that would be difficult or impossible to manufacture using traditional methods. This newfound design freedom enables engineers to push the boundaries of innovation, resulting in unique products tailored to specific needs. The ability to easily modify designs and produce them on-demand also supports agile development processes.

4. In-House Production and Localized Manufacturing

3D printing enables manufacturers to produce components in-house, reducing reliance on outsourced suppliers. This capability not only minimizes lead times but also allows for better control over the production process. By integrating 3D printing, companies can respond rapidly to changes in design or production needs, enhancing overall efficiency.

5. On-Demand Production and Inventory Management

Another significant advantage is the capability for just-in-time production. This reduces the need for maintaining large inventories, thereby minimizing storage costs and waste. Manufacturers can produce parts as needed, ensuring that components are available precisely when required.

Conclusion

In summary, 3D printing services significantly empower designers and engineers by enhancing their ability to prototype quickly, reduce costs, and innovate with unprecedented freedom. As this technology continues to evolve, its impact on various industries is expected to grow, paving the way for a more efficient, sustainable, and innovative future in manufacturing.